Success Story with DIOSNA

From craftsmanship to high performance. No more baking small rolls? This is possible with the W 401 A spiral mixer from DIOSNA. Up to 400 kg of...

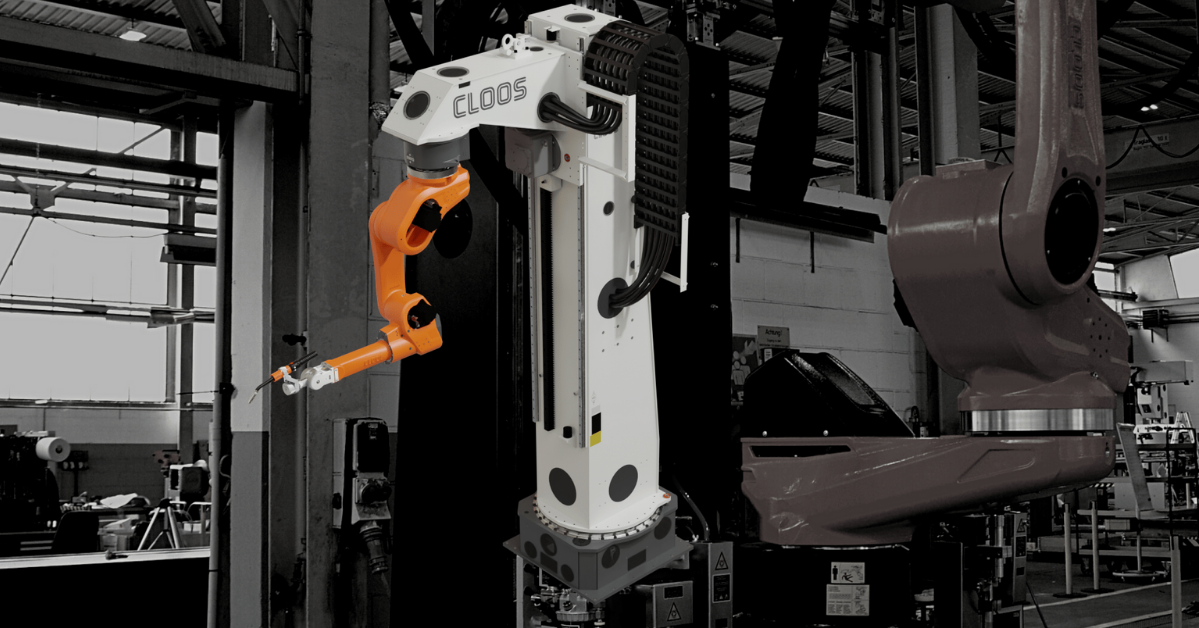

About Carl Cloos.

Robotics and automation are two of the absolute key technologies when it comes to the mechanical engineering of the future. Industrial robots and automation systems offer numerous advantages such as higher precision, efficiency and safety and contribute to improving productivity and profitability in industrial manufacturing. One company that recognized the potential of industrial robots for welding work back in the late 1970s is Cloos from Haiger am Westerwald. Carl Cloos Schweißtechnik GmbH is a leading supplier of welding technology and systems. The company is known for its innovative strength and has a long history of developing welding technologies that meet the needs of its customers.

A well-known product from Cloos is a rotating vertical stroke (robot positioner) for holding welding robots. Thanks to the increased stroke range, the robots can also process larger workpieces without any problems. The rotating vertical stroke is primarily used for production processes in metalworking and joining technology. Companies from a wide range of industries use this robot positioner in their production processes. However, this device does not come without considerable safety risks. Unintentional lowering of the vertical stroke can damage the expensive welding robot or injure workers who are currently working on the machine. Especially when moving large metal parts, it is therefore essential to install an external safety mechanism.

Carl Cloos Schweißtechnik GmbH turned to DINA for this. A particular challenge here is the built-in resolver encoder. Although it impresses with its robustness, it can only be monitored by very few available safety systems. One of these is the all-rounder for safety applications of all kinds: the SAFELINE VARIO safe small controller .

SAFELINE VARIO is the most versatile and compact safety compact control unit currently available on the market. With a width of only 45/67.5 mm (central module), the variety of applications in such a small space is unique.

The module is available in different versions, including with integrated speed monitoring and state-of-the-art comparison function. It is ideal for monitoring this type of machine, as it is already offered with resolver monitoring in the standard portfolio. In addition, the manufacturer wanted to extract this part of safety from its own control concept right from the start. We are pleased to have helped another customer out of a tricky situation and are delighted that our safe SAFELINE VARIO small controller can continue to fulfill its reputation as an "all-rounder for machine safety".

.png?width=310&height=438&name=SAFELINE-VARIO-09-24%20(1).png)

From craftsmanship to high performance. No more baking small rolls? This is possible with the W 401 A spiral mixer from DIOSNA. Up to 400 kg of...

Two strong partners, one common goal. Processing 240 pieces of wood, both softwood and hardwood, per minute? The HS flat finger jointing lines from...

.png)

Rethinking feeding. The Swedish company DeLaval specializes in the development and production of machines that are primarily used in the dairy...