Success Story with DIOSNA

From craftsmanship to high performance. No more baking small rolls? This is possible with the W 401 A spiral mixer from DIOSNA. Up to 400 kg of...

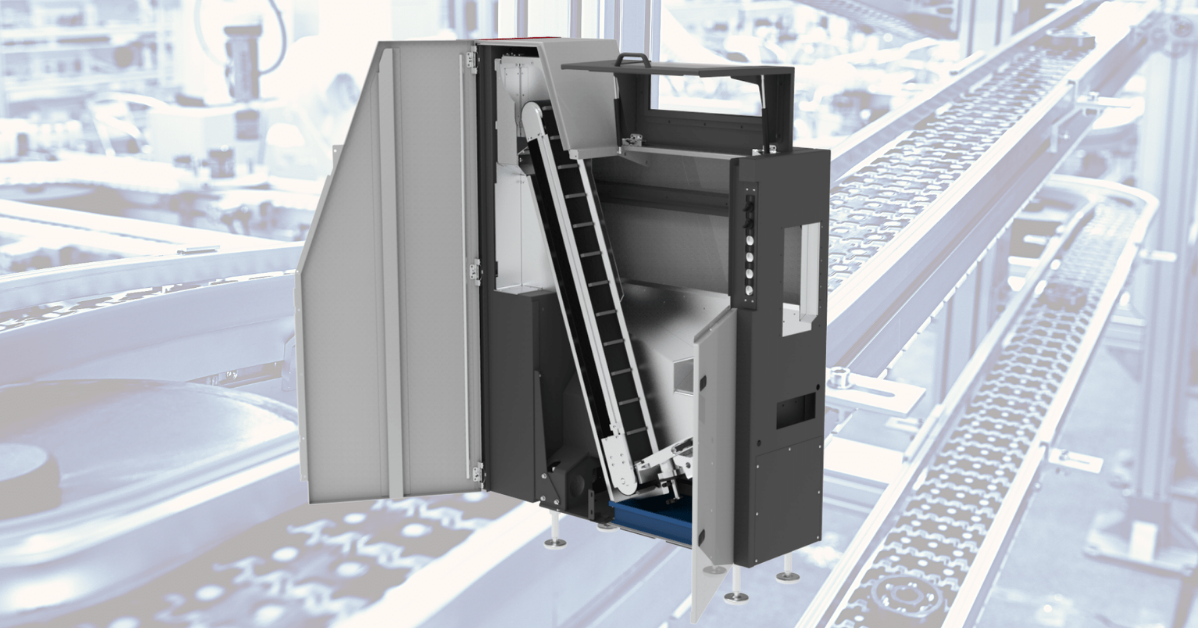

The automotive industry is the undisputed driving force of the German economy. Even though the industry is coming under increasing pressure from manufacturers abroad, it remains a flagship for Germany both at home and abroad. The production of passenger cars has many steps and involves a large number of different producers and suppliers in the supply chain. The machines used throughout the supply chain often work around the clock. No wonder that safety is a top priority for these machines. One type of machine that plays an important role in the production of components for car manufacturing is the high conveyor belts from Austrian company STIWA.

Founded as a one-man company in 1972, the STIWA Group is now one of the world market leaders in the fields of automation, production and software development. The STIWA Group stands for complete solutions in plant engineering, with a focus on fast transport systems, flexible assembly and process modules as well as intelligent software solutions, with the aim of enabling more efficient production.

The STIWA Group's high conveyor belts are real workhorses. They run 24/7 without interruption and transport individual parts, sorted and precisely aligned, to the processing or assembly station of the production plant. When loading the system, a worker actively intervenes in the machine, so the safety and protection of the operator is of the utmost importance. Due to the environment in which the machines are usually located, the long running time and volatile transport material, safety is particularly important with these machines. The STIWA Group has therefore carried out a risk assessment and minimized the existing risks to an acceptable residual risk through design measures. The risk analysis also revealed a safety-relevant problem that could not be solved by design measures: the running direction of the elevated conveyor belt. If, for whatever reason, the conveyor belt were to run in the wrong direction, this could have catastrophic consequences. Running backwards could lead to injuries to arms or hands due to crushing and shearing, work equipment could be damaged and a lot of money and time could be lost due to a conveyor stop and the associated loss of production.

In search of a simple solution, the STIWA Group contacted DINA Elektronik. Together, we then developed a safety solution that meets all requirements and protects both the equipment and the operator. By using the DN3PR1 module to monitor the direction of rotation, STIWA can easily monitor the motor's rotating field, even retrospectively. It requires no parameterization and switches the machine off immediately if the direction of rotation is in the wrong direction. Together with other design measures, workers and equipment are optimally protected against all possible damage caused by the high conveyor belt.

From craftsmanship to high performance. No more baking small rolls? This is possible with the W 401 A spiral mixer from DIOSNA. Up to 400 kg of...

Two strong partners, one common goal. Processing 240 pieces of wood, both softwood and hardwood, per minute? The HS flat finger jointing lines from...

.png)

Rethinking feeding. The Swedish company DeLaval specializes in the development and production of machines that are primarily used in the dairy...